Coatings additives

Our broad range of speciality surfactants continue to contribute to the growth of high-performance waterborne coatings additives that meet the most stringent end application requirements, are safer in use and have an improved environmental profile.

Emulsion technology is core to Croda and we therefore offer a selection of polymeric, polymerisable and non-ionic surfactants that can be used to formulate water-based coatings with enhanced film properties to meet your customer needs.

The speciality surfactants portfolio brings the following benefits:

- VOC elimination, reduction and replacement by water whilst retaining final paint film properties;

- enhanced final paint film properties such as gloss, colour development and improved drying times;

- improved coating properties such as hydrolytic stability and protection against moisture;

- optimised resin content for improved cost efficiency whilst retaining paint performance; and

- improved environmental profile.

Croda Industrial Specialties overview

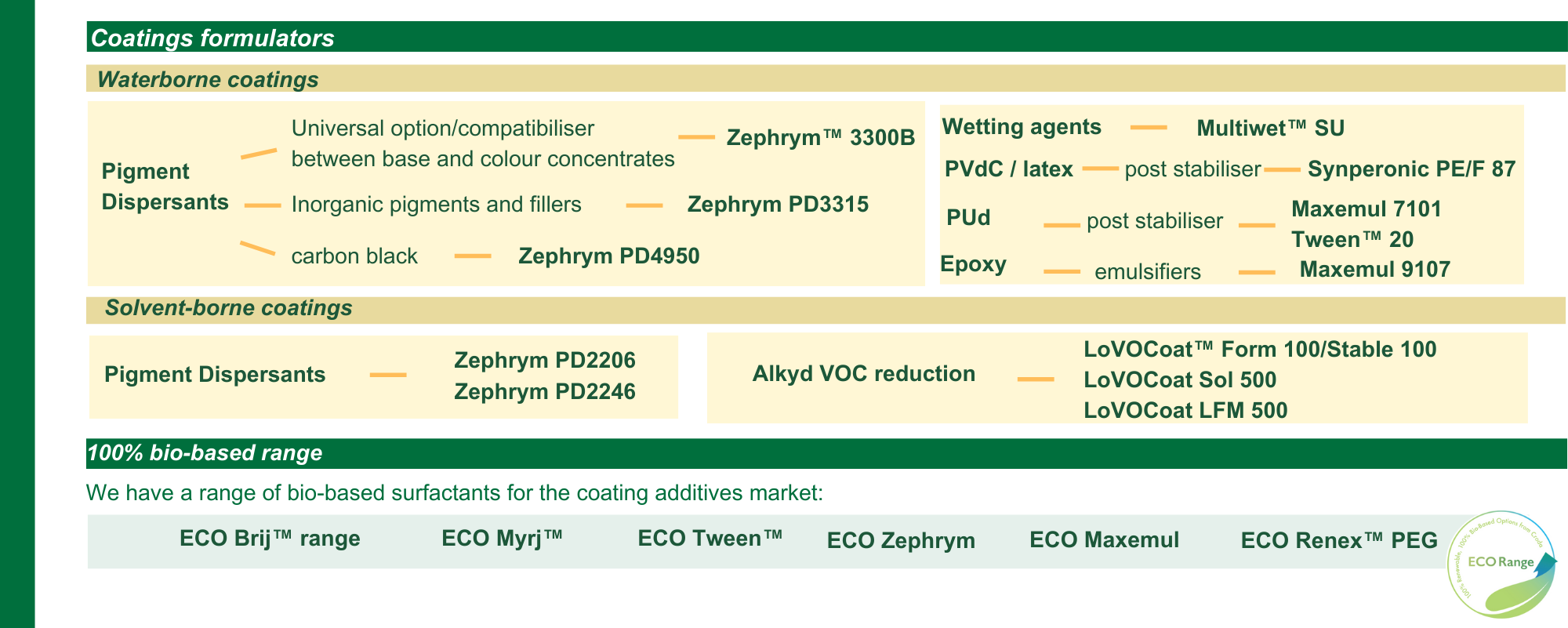

Products for coatings formulators

Products for resin manufacturers

Alkyd resin

Waterborne alkyd resin coatings

We offer a range of specialty polymeric surfactants, Maxemul 7000 series, to formulate high performing VOC free waterborne alkyd resins. Our versatile surfactant range is application to short, medium and long oil alkyds. Emulsions typically have solids content up to 55%, low viscosity, excellent shelf life and enhanced dry film properties.

Maxemul 7000 polymeric surfactants bring the following benefits in use:

- Formulation of cost-effective VOC free alkyd resins

- No reformulation of the alkyd required

- Good compatibility with pigments and rheology modifiers

Alkyd resin product selection

Maxemul 7201 and Maxeul 7101 (recommended)

or Maxemul 7201 and Maxemul 7102

Short oil alkyd resins:

Maxemul 7201 and Maxemul 7102

Coatings formulations

Croda offers formulation guidelines and a variety of emulsification processes tailored to your needs:

- Direct-to-Metal coating formulation

- Flat wall paint formulation

- Low VOC High Gloss Trim Paint formulation

Cost and VOC reduction in solvent-borne alkyd based paints

LoVOCoat surfactant will allow you to formulate with water as liquid filler in solvent-based paint formulation and provides formulators these benefits:

- Formulate low VOC high quality alkyd paint

- Cost savings by replacement of solvent with water without impacting performance

- Low VOC alkyd paint with fast drying time

- Minimal impact on hardness, gloss retention and film transparency

- Regional product availability

LoVOCoat range

VOC reduction for solvent based paints

- LoVOCoat Sol 500: 50% w/w concentrate, for pre-emulsions

- LoVOCoat Form 100 / LoVOCoat Stable 100: 20% in D80/water, for direct water incorporation

- LoVOCoat LFM 500: for more polar alkyds (high OHV)

Emulsion polymerisation

Reactive surfactants, MaxemulTM 5000 and 6000 series, are being used in acrylic and vinylic waterborne binders to enhance performance in wall paints,

wood coatings and metal protection, pressure sensitive adhesives and others. Maxemul reactive surfactants for emulsion polymerisation are emulsifiers

that copolymerise with the main monomers during the polymerisation process and remain evenly distributed in the dry film, improving the end use

properties of emulsion polymers.

These products offer the following benefits to the latex and dry film:

- Protection - enhanced scrub resistance, faster drying, increased water, stain and salt spray resistance;

- superior adhesion to the substrate; and

- good appearance - higher gloss and gloss retention; non-whitening in humid conditions.

| Product | Chemistry | Description | HLB | Property |

| Maxemul 5010 | Copolymerisable surfactant (non-ionic) | For emulsion polymerisation dry films with excellent moisture resistance, electrolyte tolerance |

13.1 | Liquid |

| Maxemul 5011 | Copolymerisable surfactant (non-ionic) | For emulsion polymerisation dry films with excellent moisture resistance, electrolyte tolerance |

16.1 | Liquid |

| Maxemul 6106 | Copolymerisable surfactant (anionic) | For emulsion polymerisation dry films with excellent moisture resistance, electrolyte tolerance |

Viscous liquid paste | |

| Maxemul 6112 | Copolymerisable surfactant (anionic) | For superior emulsion stability in latex copolymerisable/systems and excellent moisture resistance or adhesive properties in coatings |

Waxy paste | |

| Maxemul 6112/20 | Copolymerisable surfactant (anionic) |

20% active in water for easy handling |

Liquid |

Why reactive surfactants?

Maxemul reactive surfactants are emulsifiers that copolymerise with the monomers during the polymerisation process and remain evenly distributed in the dry film, dramatically improving performance properties of emulsion polymers.

Maxemul surfactants are grafted onto the surface of polymer particles and thus enhance latex stability properties. The absence of free surfactants in the dry film results in film properties with equivalent performance to solvent-borne resins.

Superior colloidal stability of the latex and formulated system increases:

- pigment binding;

- shear and freeze/thaw stability; and

- stability even in the presence of high levels of coalescent and alcohols.

Enhanced properties and durability of the dry film:

- Coating protection

- Higher scrub resistance

- Increased water, stain, blocking and salt spray resistance

- Drying speed

- Multi-substrate adhesion

- Ultimate appearance

- Higher gloss and gloss retention

- Non-whitening in humid conditions

Additives

100% bio-based ECO range of surfactants

We offer to the market non-ionic and anionic surfactants, which are used as wetting agents, emulsifiers, co-emulsifiers, stabilisers in emulsion polymerisation and dispersants. We also offer PolyEthylene Glycols (PEGs) and vegetable oils used in many applications.

Discover our ECO range of 100% bio-based surfactants and PEGs. Over 50 products make up the ECO range made by using bio-based ethylene oxide (EO) which we manufacture from biomass ethanol. Coupling the use of bio-based EO with the high proportion of renewable energy used at the manufacturing plant, leads to a significant reduction in carbon footprint for the ECO product range. Formulators can now access 100% renewable surfactants without sacrificing performance to help meet increasingly demanding sustainability targets.

Croda's range of ECO surfactants

- 100% renewable

- Performance identical to petrochemical based options

- Lower carbon footprint than petrochemically derived ingredients

- USDA BioPreferred® Program third party certification*

- Made using renewable energy

*Calculated using ASTM D6866 which is validated by carbon 14 testing

100% bio-based ECO range

Coatings additives product offering

- Ethoxylated natural fatty alcohols – ECO Brij series

- Ethoxylated sorbitan esters – ECO Tween series

- PolyEthylene Glycols – ECO Renex PEG series

- Ethoxylated castor oil – ECO Etocas series

- Ethoxylated hydrogenated castor oil – ECO Croduret series

- Ethoxylated natural fatty acids – ECO Myrj series

Ethoxylated natural fatty alcohols

Sorbitan esters and ethoxylates

Polyethylene glycols (PEGs)

Alkoxylated block copolymers

Polymeric dispersants

Seatons natural oils

Vegetable oils for a diverse range of markets such as construction, inks, lubricants and paints. Our Seatons range of oils are processed to tailor their properties. We have different grades of oils from the following raw materials:

- Linseed oil

- Rapeseed oil

- Castor oil

- Refined soyabean oil

- Refined sunflower oil

- Emulsifiable sunflower and safflower oils

Epoxy

Waterborne epoxy emulsions can be formulated easily using standard epoxy resins (type 828 and 1001) and Maxemul 9107 polymeric surfactant. This is a non-ionic polymeric surfactant that has been selected to formulate oil in water (O/W) epoxy emulsions with fine particle size and excellent tropical storage stability.

Maxemul 9107 is a versatile surfactant that can be formulated into:

- Type 1 solid epoxy O/W emulsions

- Liquid epoxy resin O/W emulsions

- Solid/liquid epoxy resin O/W emulsion blend

Waterborne epoxy emulsion formulations

Croda has developed different emulsification processes to meet your requirements

- Direct-to-Metal coating formulation

- Liquid epoxy resin O/W emulsion

- Solid epoxy O/W emulsion

- Epoxy Resin O/W Emulsion Blend of LER/Type 1 SER

Maxemul 9107 cold processing

Not sure how to formulate?